Laser Cutting

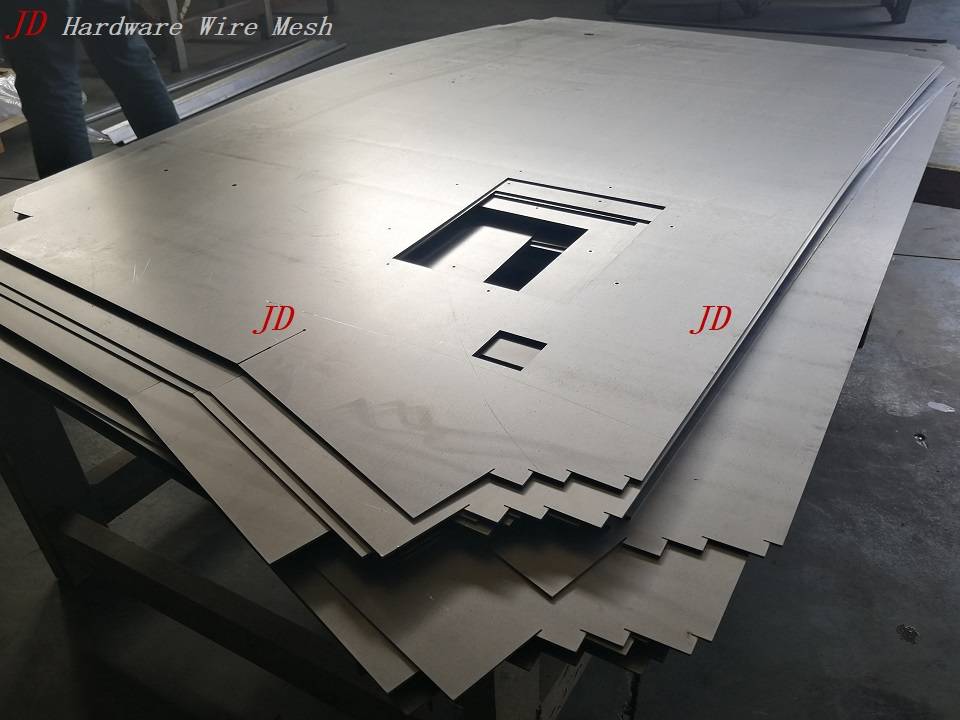

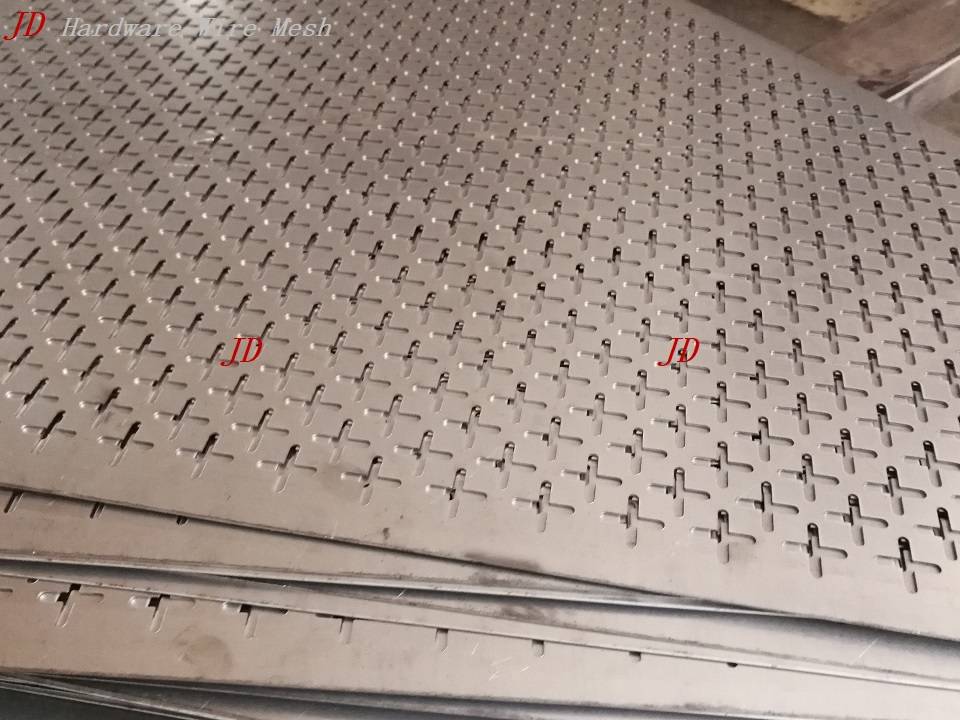

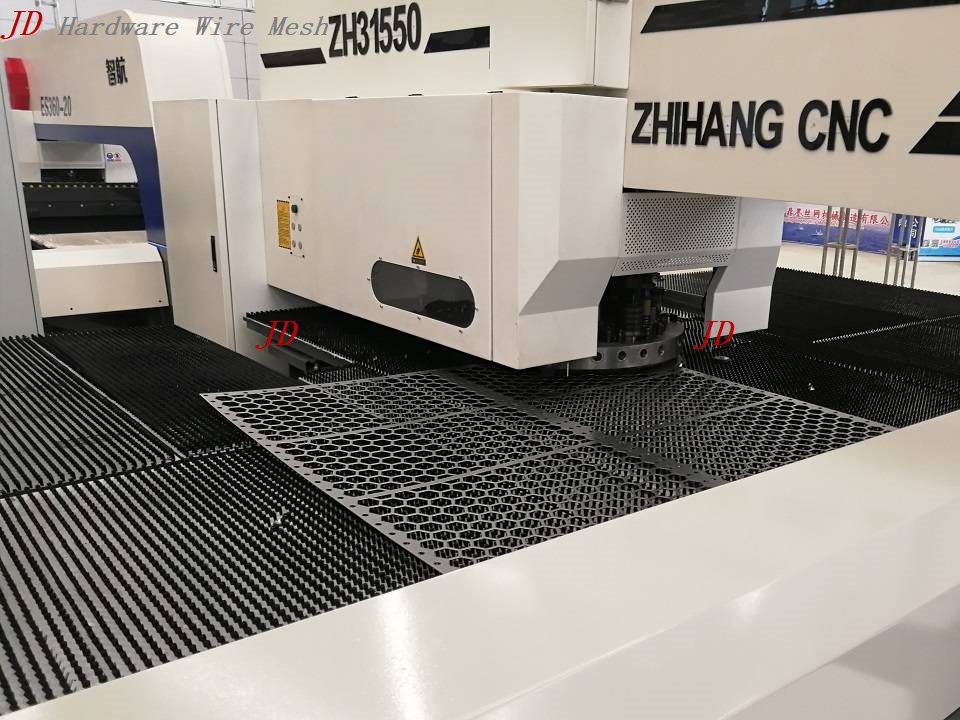

We've invested in hi-tech laser cutting methods for fast and accurate melting and burning of metals. Using the latest in software and engineering technology, our professional team can arrange for your order to be tailored and delivered to your exact specifications. Our laser cutting service is so good, we can make almost anything out of metal!

What is Laser Cutting?

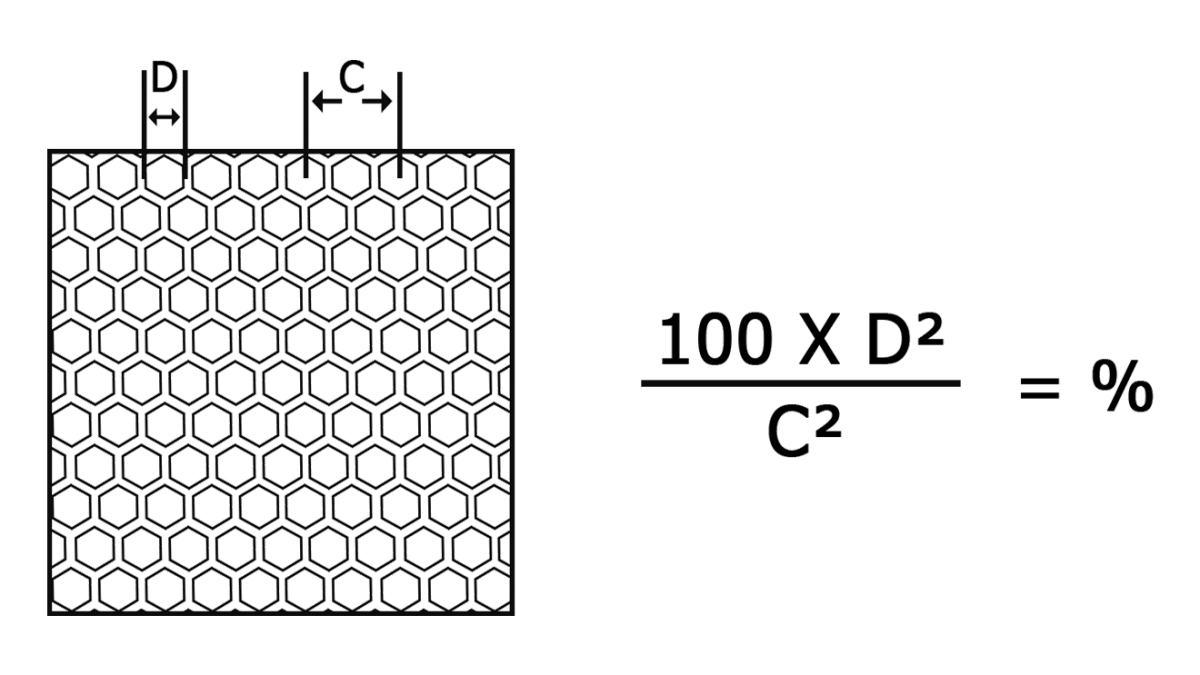

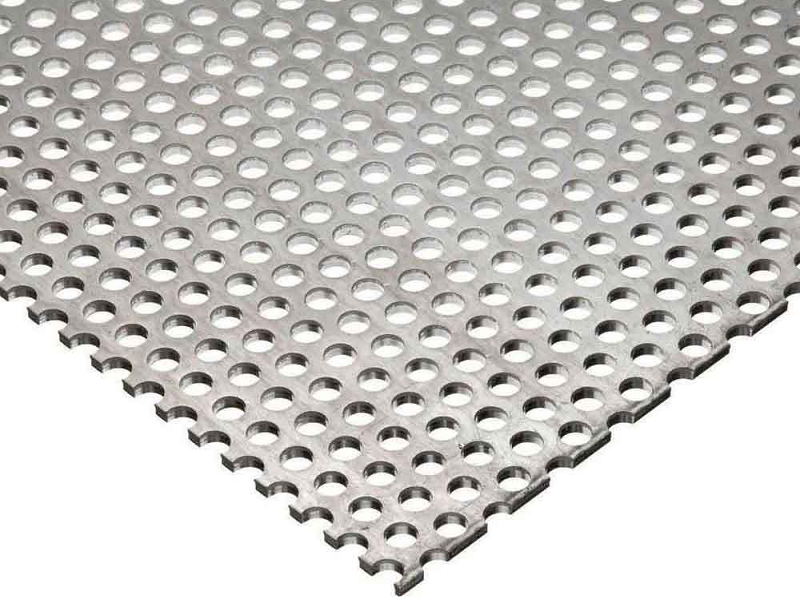

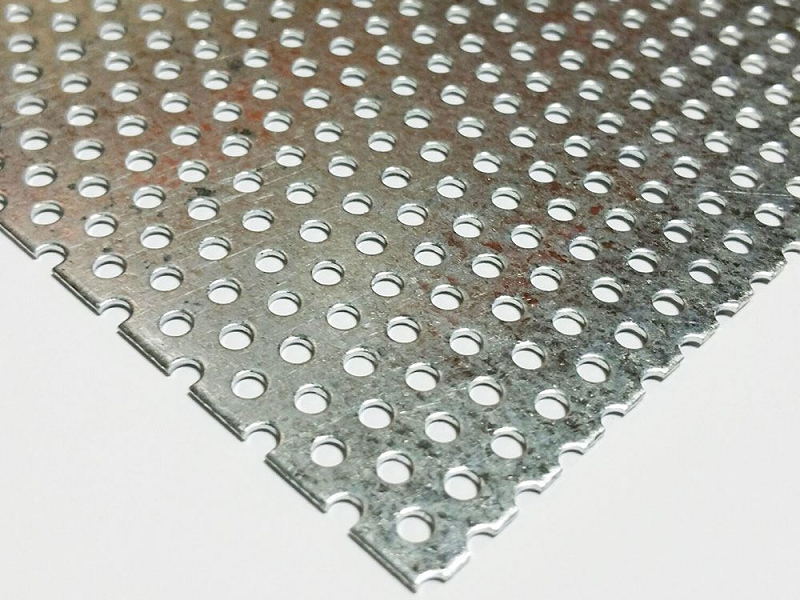

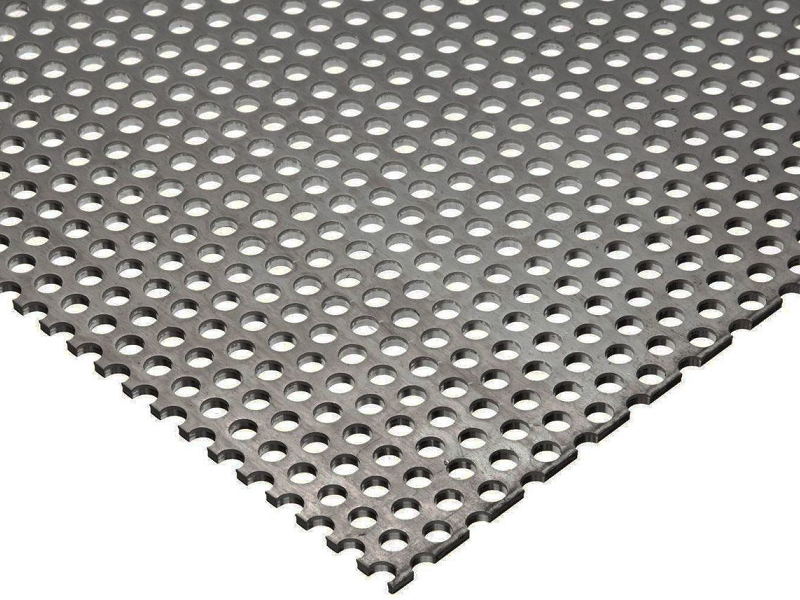

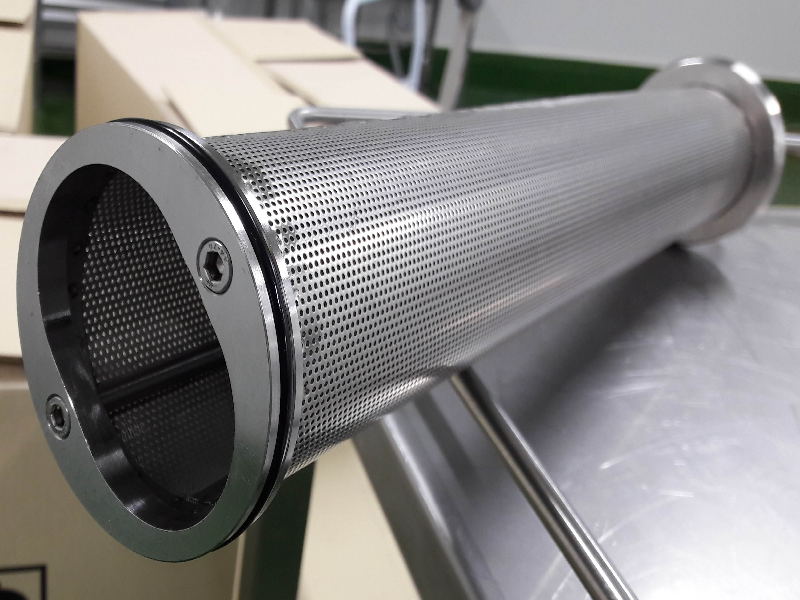

Laser cutting is used for both cutting materials unlike metal, stainless steel, aluminum, bimetal and iron and for industrial production. Optically laser cutting is accomplished by directing the output of the high power generating laser. Additionally there is a motion control system that follows G or CNC code used commercially in laser applications. In this way patterns are processed on the material. The laser beam melts the material, thus burning it and evaporating. In this way a high-quality surface with a coated edge is obtained. Industrial laser cutter can cut into flat sheet materials as well as pipe and profile materials.

Laser Cutting Advantages

- Laser cutting is very advantageous in metal cutting. These studies are very important in terms of reducing the adaptability and usability of the workpiece. In this way, sensitivity is better. The main reason for this is that the laser beam does not cause wear during the process.

- The area affected by heat is small in laser cutting. Therefore, the cut material does not deteriorate. In particular, the cutting of certain materials by conventional methods can present very important problems.

- Laser cutting of metals provides less energy. Industrial laser machines in particular can cut larger thicknesses using less energy.

- Significant errors are eliminated in the production phase.

- Very important facilities can be provided in mass production. However, the cost decreases as well as the increase in production. This enables a significant saving.

Laser Cutting Methods

There are many different methods for cutting different materials. When the right material is combined with the right method, more successful and efficient results are obtained.

- Standard work is carried out by evaporation cutting method. In this method, a key hole is formed on the heated surface at the boiling point. Cooling is performed quickly to deepen the hole. The material will become boiling in the deepening hole. In this way, thermoset plastics, carbon and wood materials are cut.

- High pressure gas is used in the melting method. In this method for cutting bimetal materials, the material is heated to the melting point. The molten material is then discarded from the process. With the temperature of the material there is no need to lift up. With this method, metal materials are cut.

- Semi-rigid materials are used in thermal stretching method. The beam focusing on the surface creates thermal expansion. This creates a crack that allows the beam to move. This method is used for glass cutting.

- With the fluidity method in the form of silicon microelectronic chips silicon plug. The wavelength is 1064 nm and constitutes the YAG laser-powered process.

- Reactive cutting is known as flame cutting. The oxygen torch can be described as cutting. The ignition source is laser cutting beam. This method is used to cut materials over 1 mm of carbon steel. In this process, thicker plates can be cut using less laser power.

Laser Cutting Application Areas

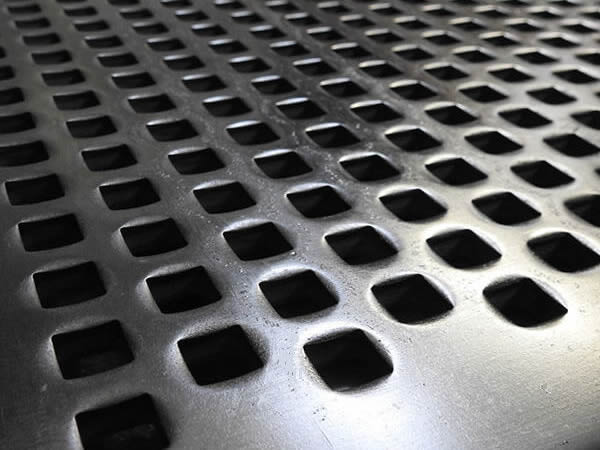

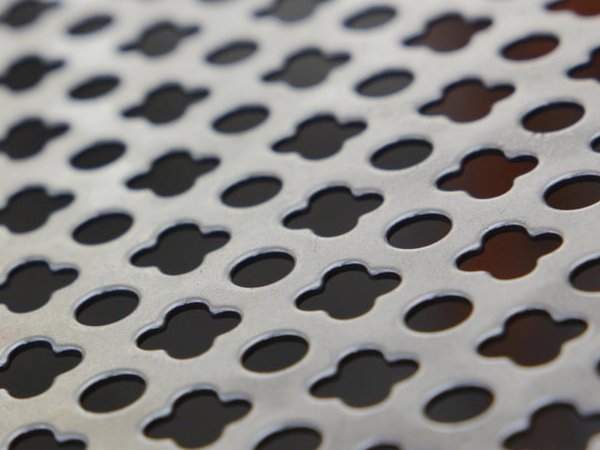

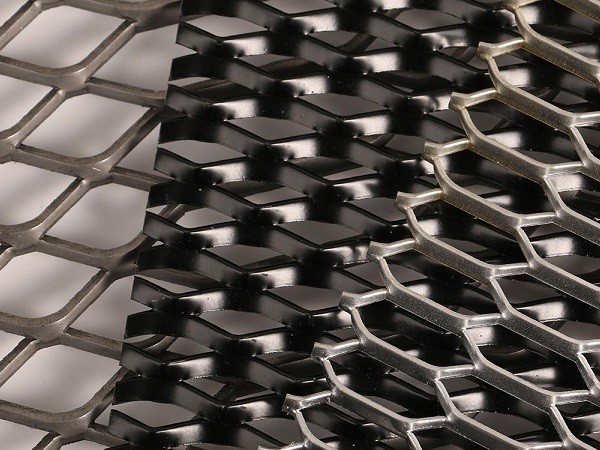

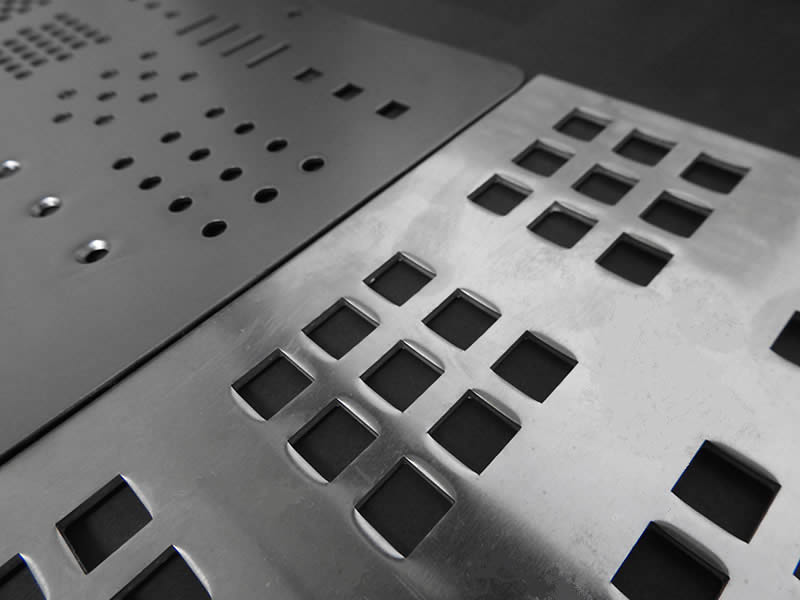

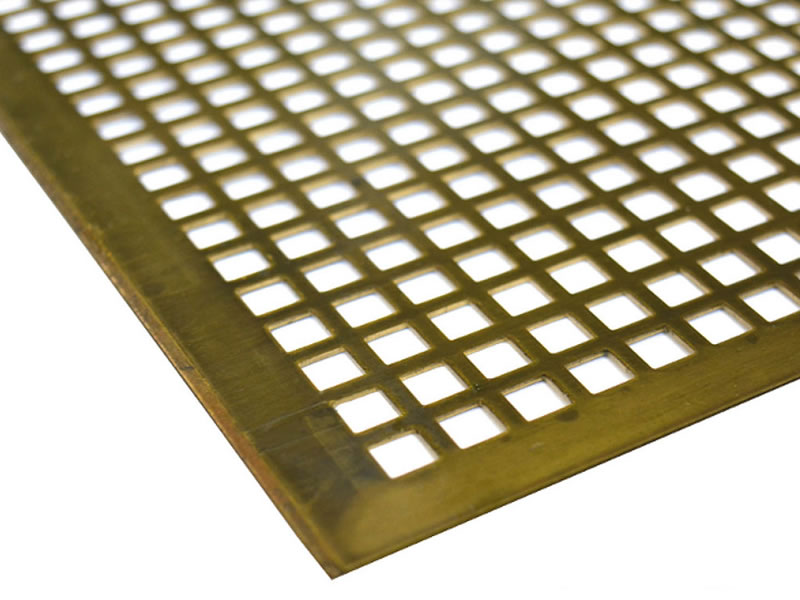

With laser cutting applications, which are one of the most used production processes in the world, we produce exact solutions to the needs of every sector. From aviation to automotive, quality is offered in every sector with different advantages. Laser cutting, which has a very important place in medical, semiconductor and electronic sectors, is preferred in material production and processing. These applications, which are mostly used in cutting and drilling areas in engineering applications, provide automation in the production. Laser cutting applications used in interior spaces and facades create aesthetic solutions. With our high quality and efficient works, patterns and motifs can be embroidered on the desired area easily.