Customized Welding

The ability to produce high-quality welds efficiently and consistently is a vital manufacturing function.

Products We Welding

JD has advanced welding equipment and multiple welders on staff at each service center. Our welders are skilled and qualified. We are keeping on providing high-quality MIG, TIG, and arc welding services for your customized products. The mainly products need welding as follows.

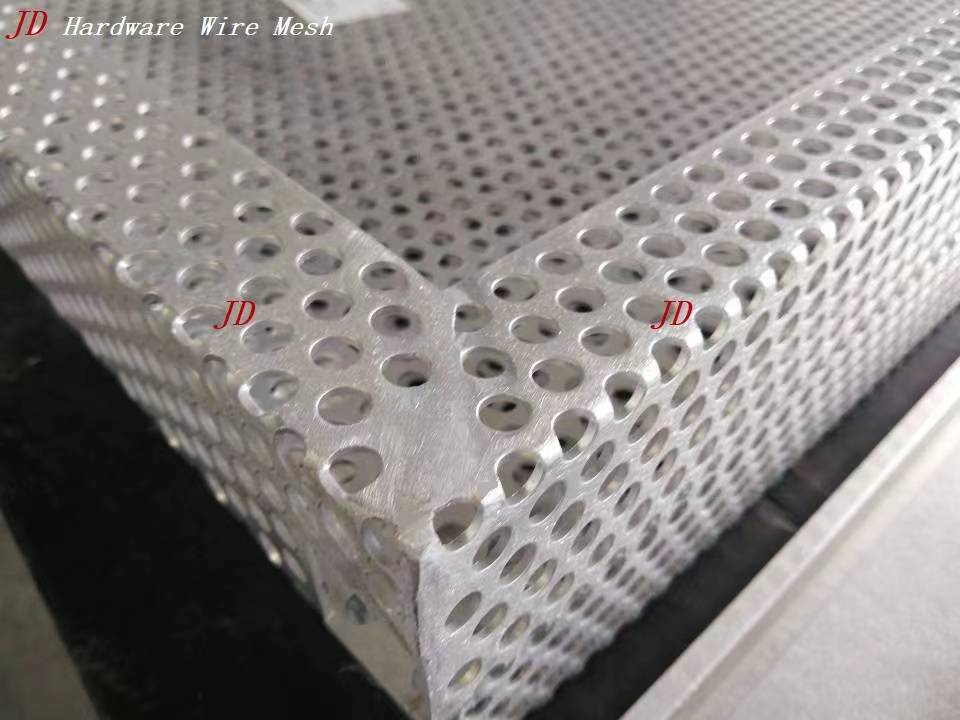

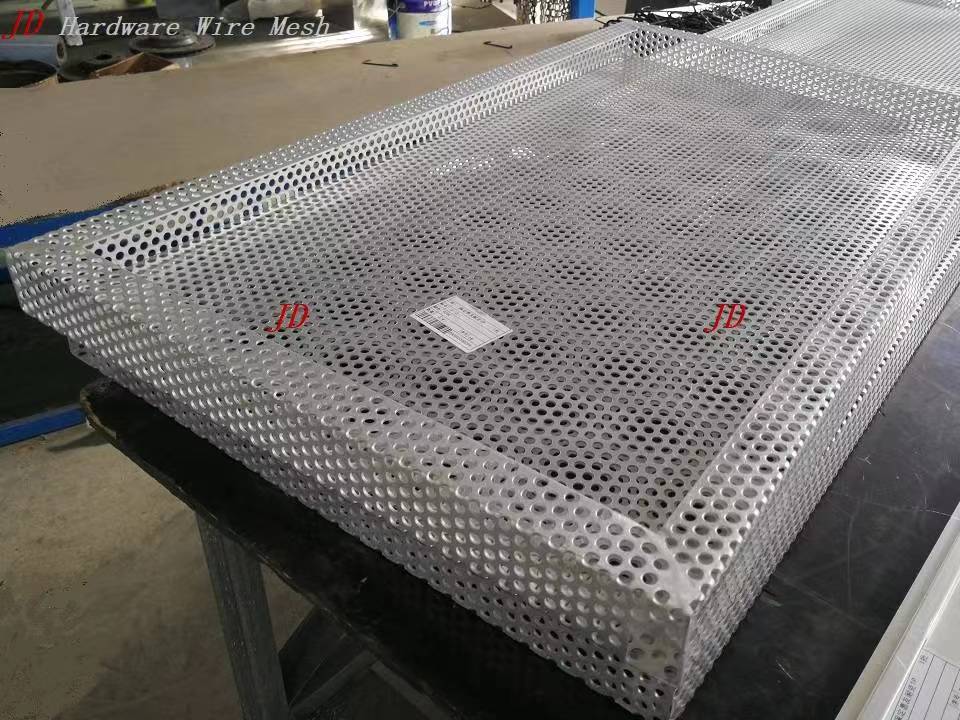

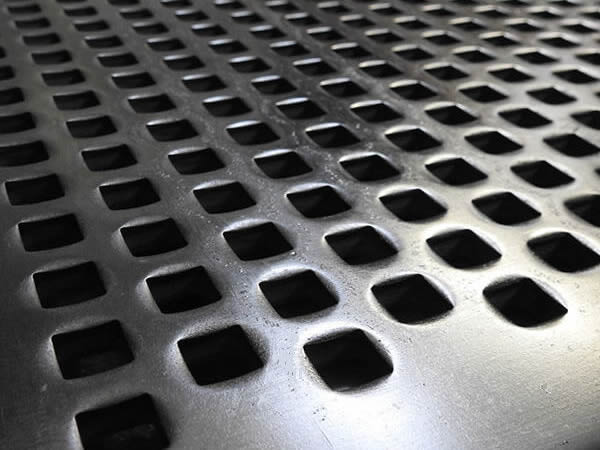

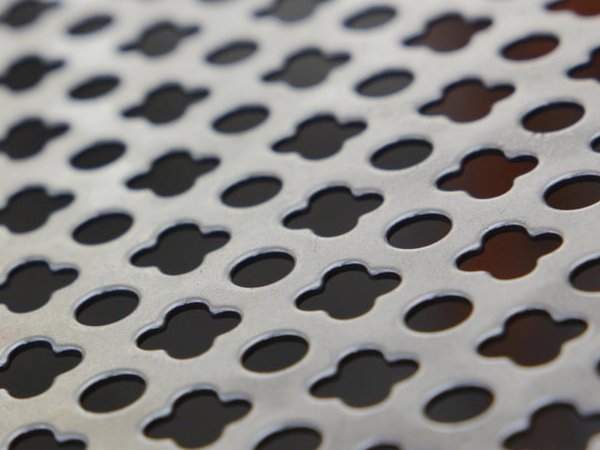

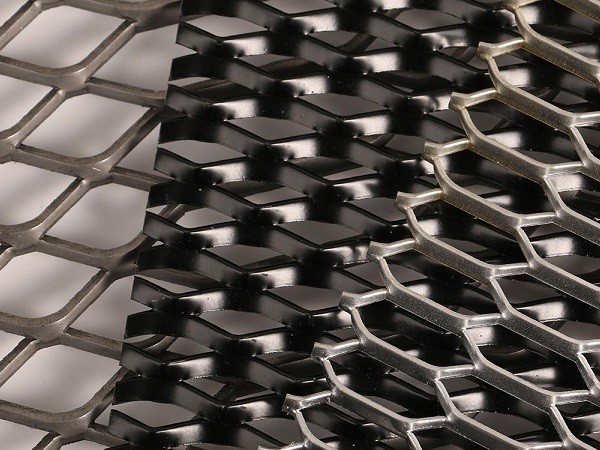

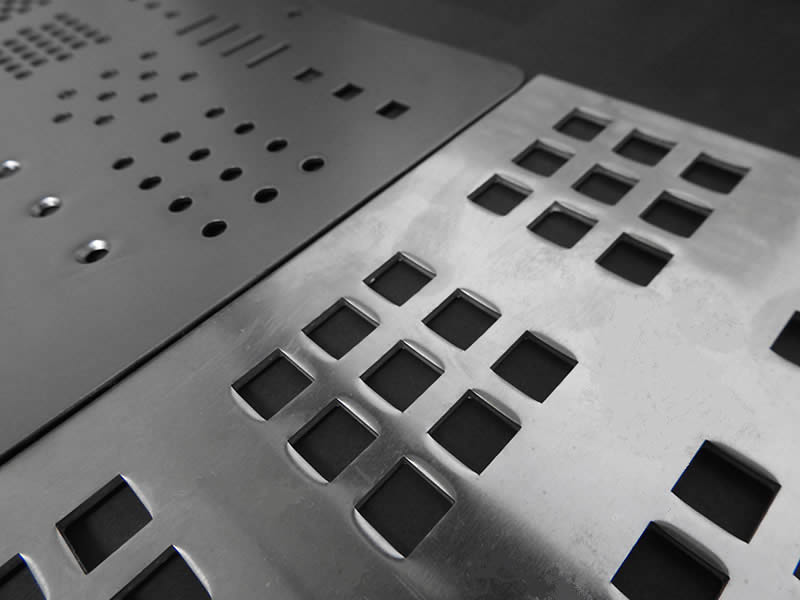

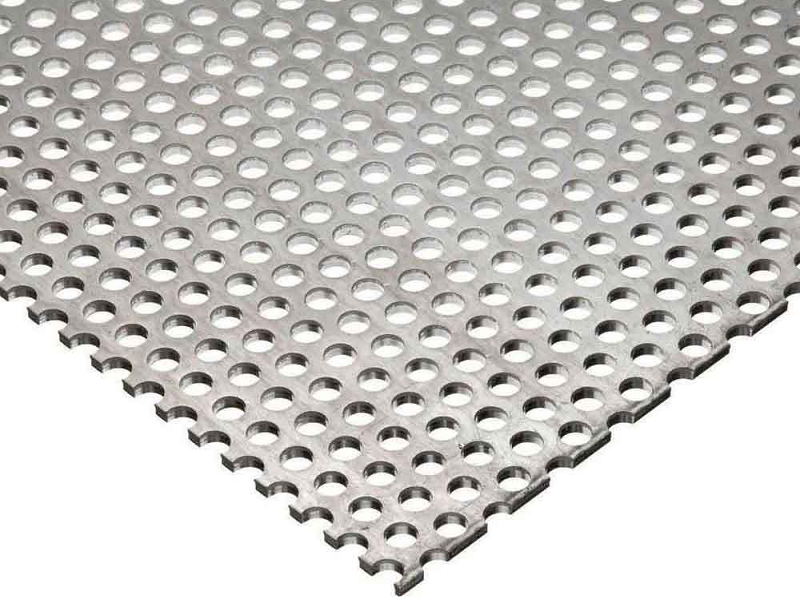

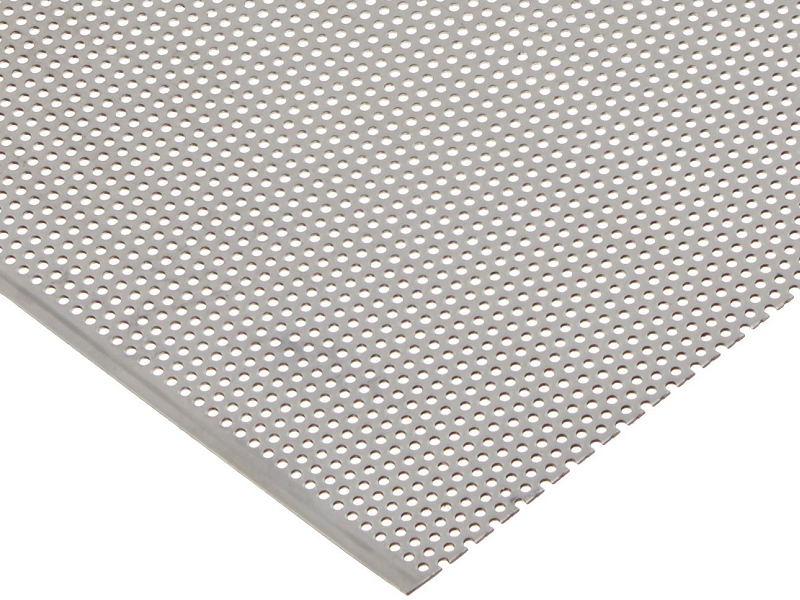

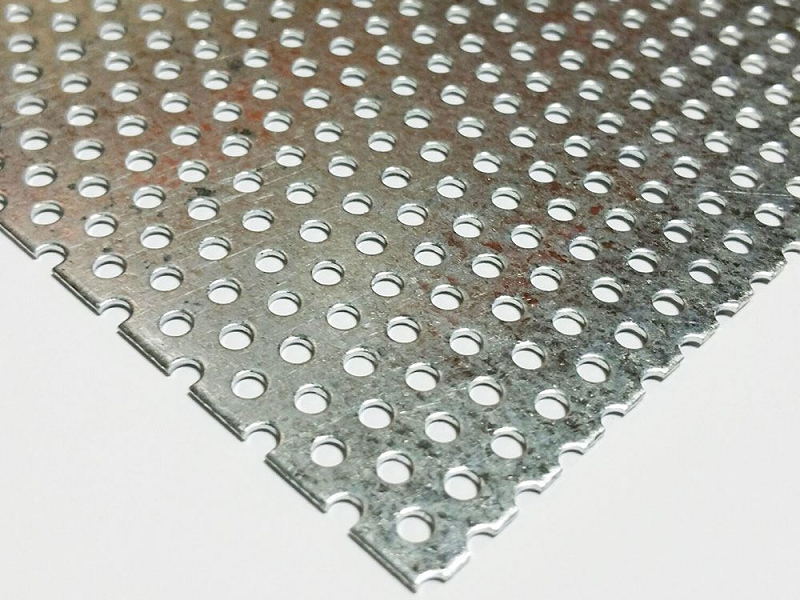

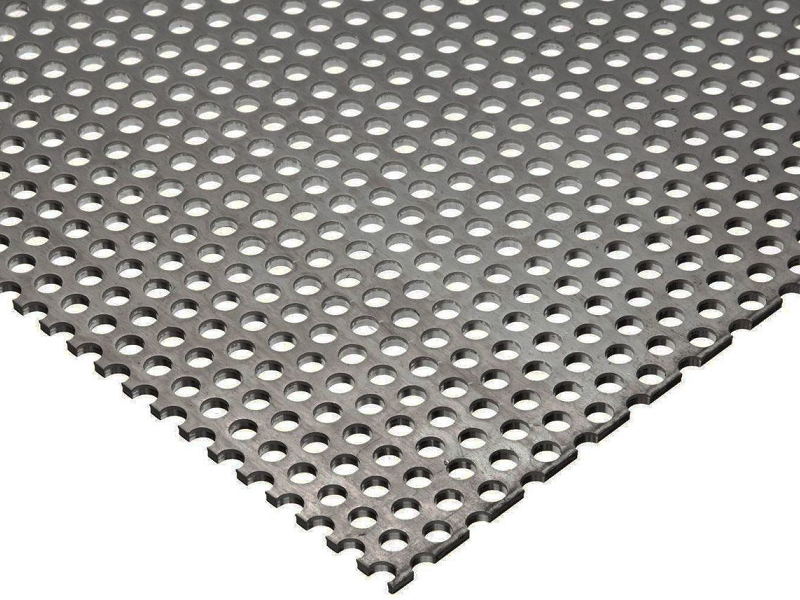

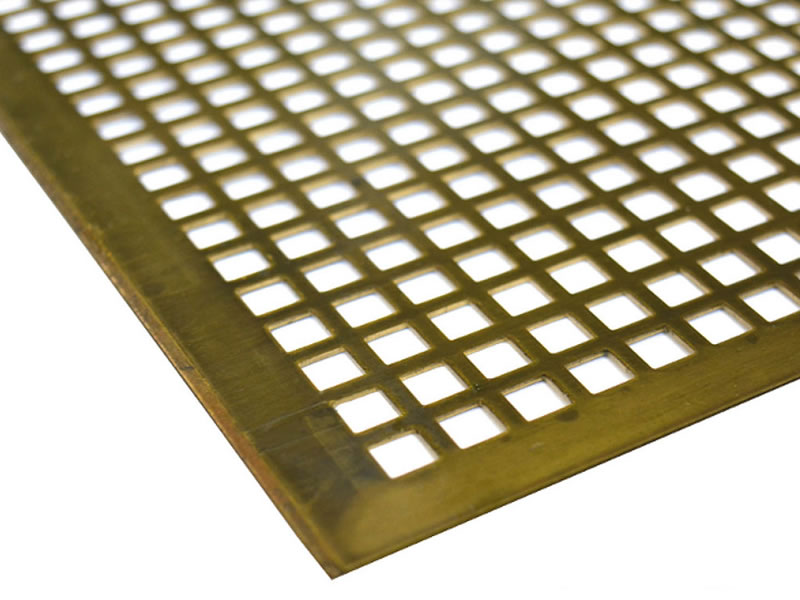

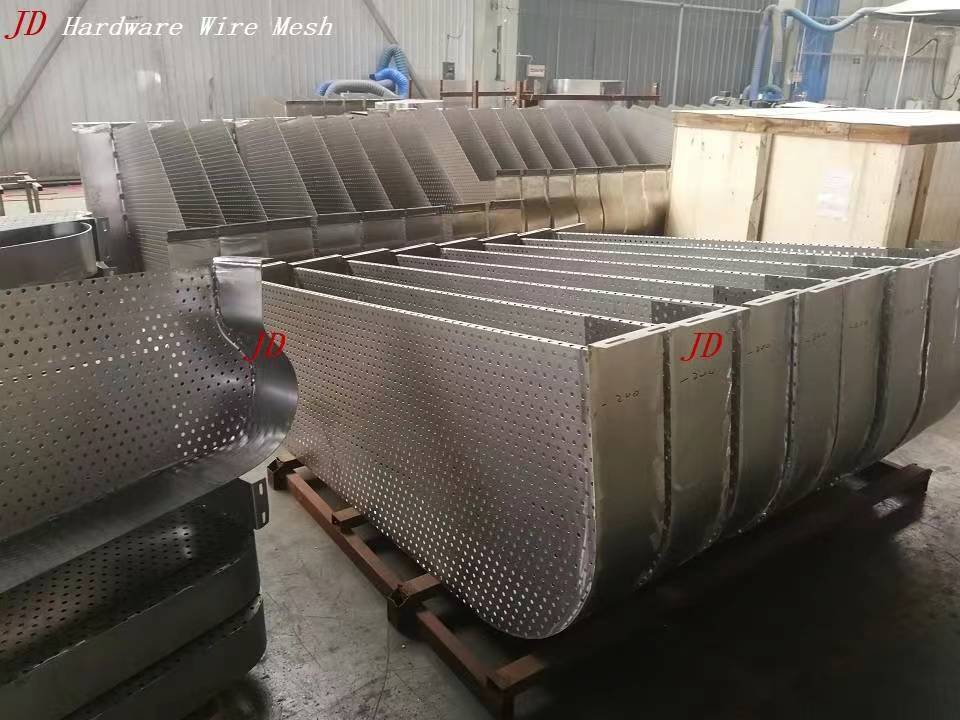

Perforated Metal wire mesh, Expanded Metal mesh, and other metal wire mesh

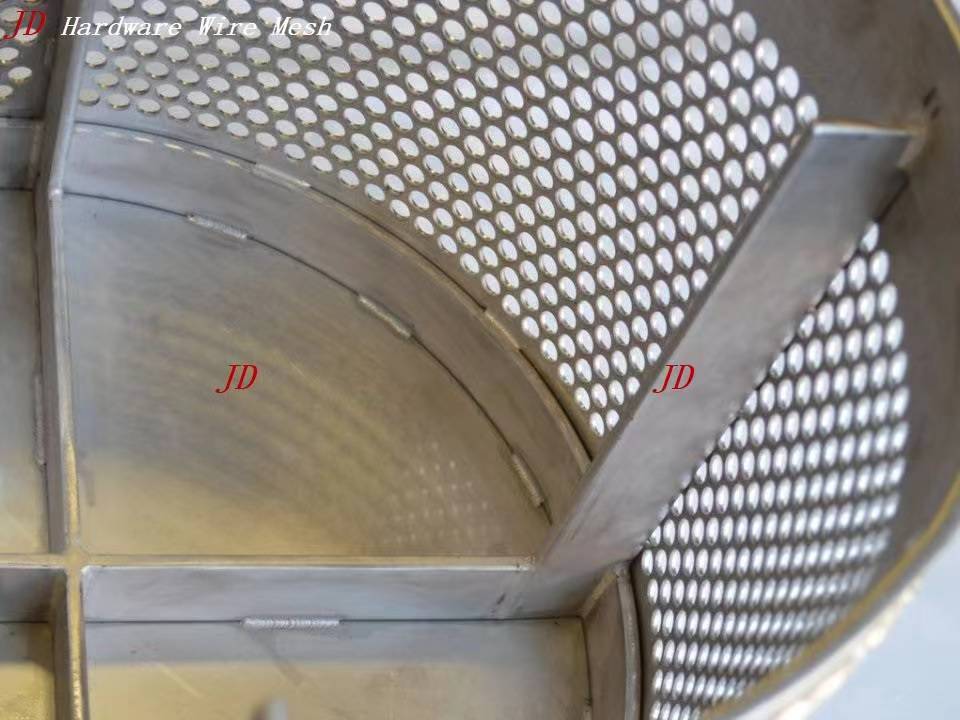

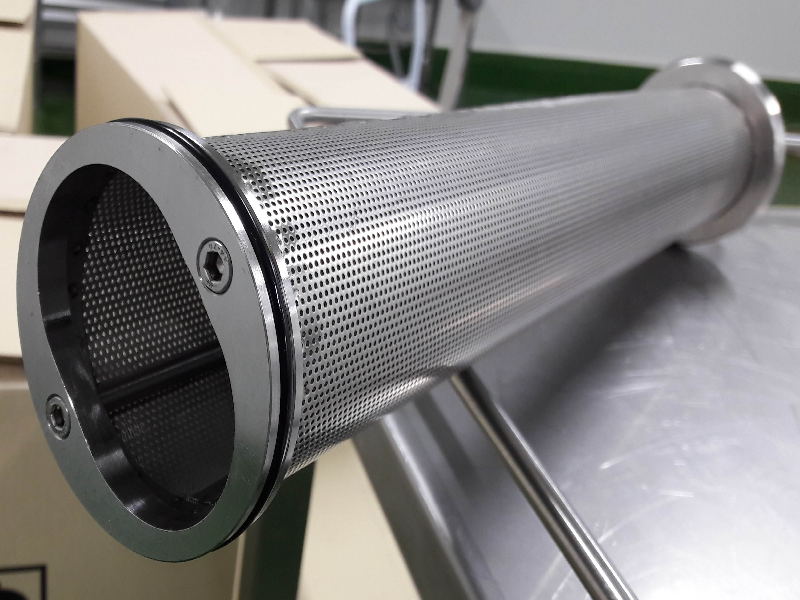

Perforated metal deep process into cylinder, baskets, filter elements

perforated metal safety gratings tread

Wire screen deep processing products including DSM screen, rotary screen, nozzle filter, T intake screen, solid-liquid separation screen, etc.

TIG Welding

Tungsten inert gas (TIG) welding, also known as gas tungsten arc welding (GTAW), is a process that joins metal using a pointed tungsten electrode activated by an electrical current. The intense heat of a TIG arc is formed between the electrode and the metal workpiece, heating it to a melting point. An inert “shielding” gas, usually argon or helium, is blown onto the workpiece to keep contaminating particles away from the work.

The small TIG welding point enable welders to produce very accurate, high-quality welds. TIG is quite difficult, so only the most experienced and well-trained welders are able to produce quality TIG work.

Although not the fastest process, TIG can reduce production costs by eliminating secondary operations like deburring or polishing.

Benefits of TIG:

Inert gas eliminates spatter and slag, resulting in clean, cosmetic welds

No consumable elements to cause work stoppage

Produces strong, high-quality welds that meet strict structural or code requirements

Can be used on a wide variety of metals

Joins thin metals with less distortion

Ideal for projects that require extreme precision

Drawbacks of TIG:

Complex and very difficult to learn

Slower than other welding processes

Tools and machinery are costly

Does not perform well with thick metals

MIG Welding

Metal inert gas (MIG) welding, also called gas metal arc welding (GMAW), is a process in which an electric arc forms between a spool-fed wire electrode and metal workpieces. A MIG arc heats the workpieces quickly, causing them to melt and join almost instantly. Argon or helium shielding gas helps prevent atmospheric contamination of the workpiece. Equipment consists of a welding gun, a power supply, a shielding gas supply, and a wire-drive system which pulls the wire electrode from a spool and pushes it through the welding gun to the work.

Benefits of MIG Welding:

Produces high-quality welds quickly

Much easier to learn

Welds long stretches of material without stopping, creating a manufacturing advantage

Uses inert gas to defend the arc and reduce spatter and slag, resulting in cleaner welds

Works well with a wide variety of metals and alloys

Applicable to semi and fully-automated production

Drawbacks of MIG Welding:

Cannot be used in the vertical or overhead welding positions

The equipment is complex

Not as precise as TIG

Spot Welding (ERW)

Spot welding, also known as electric resistance spot welding, is a process where two or more portions of sheet metal or wire mesh are instantly and permanently joined using intense heat generated by a strong electric current. The process generally uses two opposing L-shaped copper alloy electrodes to first clamp the sheet metal together, then concentrate current into a small “spot”, producing the welded joint. The electric current is provided to the electrodes by a switched power supply that can store, transform, and deliver current in a quick, intense burst. The amount of current can vary depending on material thickness for optimum weld performance.

Spot welding can be automated with robots and controlled by computer programs. This makes spot welding a great choice for manufacturing auto bodies, metal housings and containers, and other fabricated sheet metal products. Spot welding can be used on a variety of metals, but aluminum requires more current due to its much higher thermal and electrical conductivity.

Benefits of Spot Welding:

Produces very fast, efficient welds

Ideal for automated factory settings

Does not require high skill levels

No consumable elements to cause work stoppage

Avoids heating other areas of the sheet metal

No open flame or arc

Welded spots are small and can be accurately positioned

Drawbacks of Spot Welding:

Joints may not be as strong as other types of welded joints

Joints are rough-looking. Joints exposed to the end user must be painted or plated

Current must be carefully controlled to avoid weak joints

Certain spots may be difficult to reach with two electrodes, requiring specialized equipment

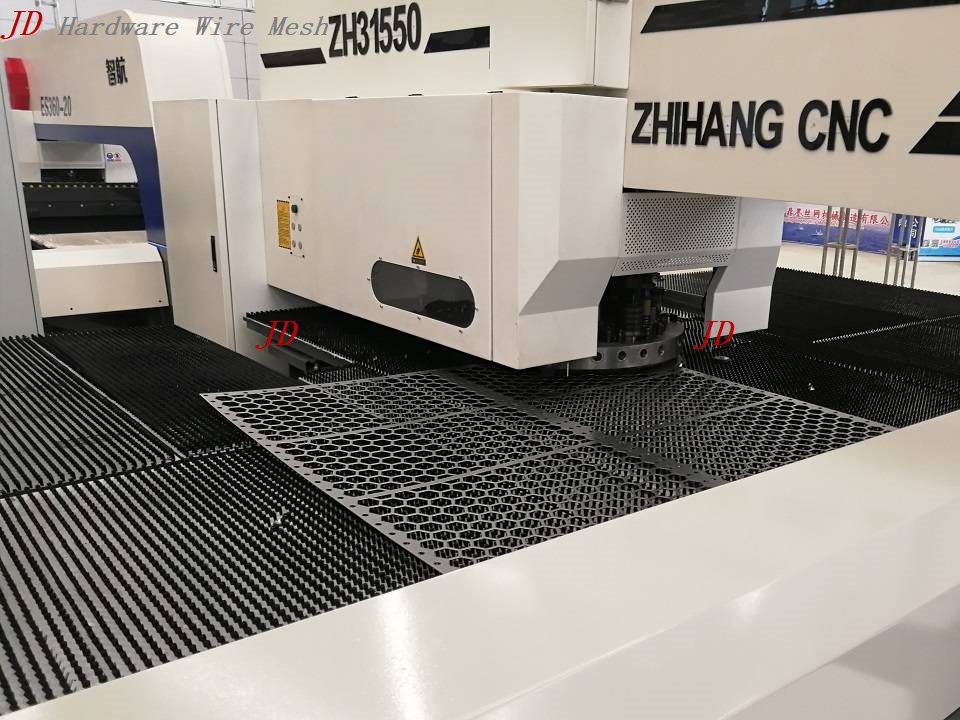

Welding Automation

Automated welding provides manufacturers with huge gains in efficiency and quality. Welding automation can be broken down into two basic categories: semiautomatic and fully automatic.

In semiautomatic welding, an operator manually loads workpieces into a fixture. A weld controller then engages the welding appliance and completes the weld according to preset parameters. After the weld is completed, the operator removes the welded assembly and loads the next set of workpieces. A second worker provides workpieces to the operator and collects finished assemblies to avoid production stoppage.

In fully automatic welding, a machine or robot, or a series them, will load the workpieces, position the welding appliance, complete the welds, check the quality of the joints, and offload the finished assembly into a chute or conveyor. The operator is responsible for keeping workpieces available to the machinery.

Benefits of Automated Welding:

High speeds enable huge efficiency and cost-savings gains

Consistently high quality

Far lower labor costs

Automated process controllers detect quality issues immediately

Material feeders and conveyors coupled to the system increase efficiency

Drawbacks of Welding Automation:

Higher initial investment

Longer setup time

Can’t accommodate changes as easily

Some maintenance required

Only makes sense for large quantity production