Hole Pattern

- Round Hole Perforated Metal

- Square Hole Perforated Metal

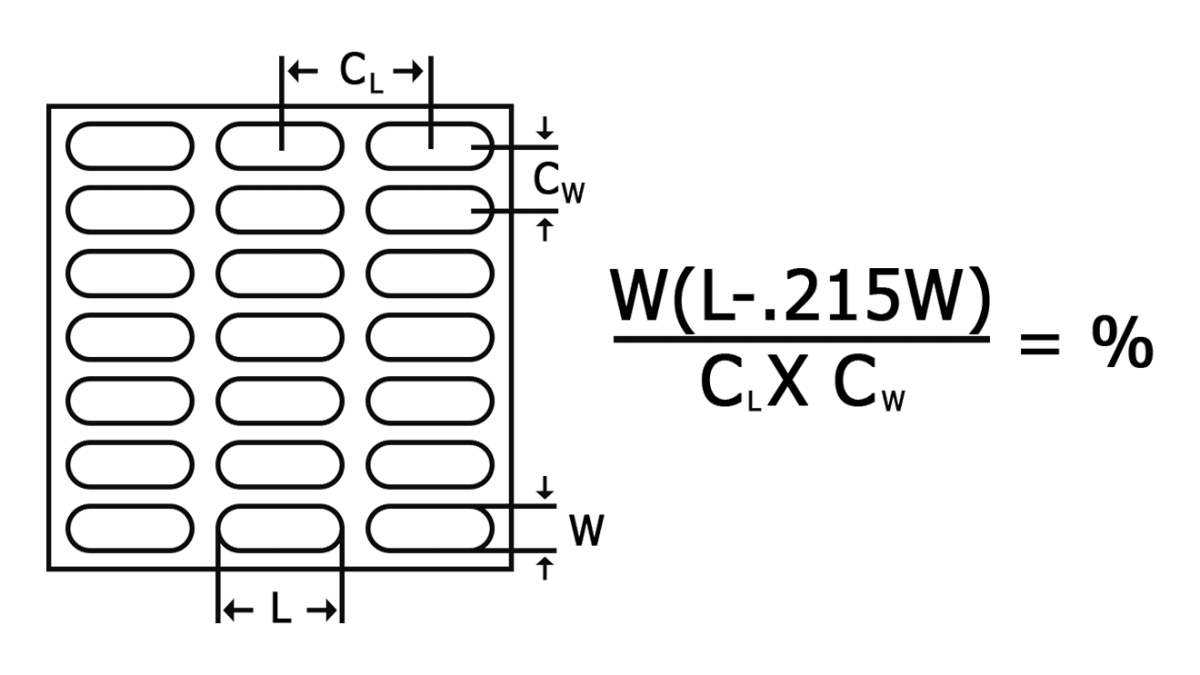

- Slotted Hole Perforated Metal

- Decorative Perforated Metal

- Expanded Metal Mesh

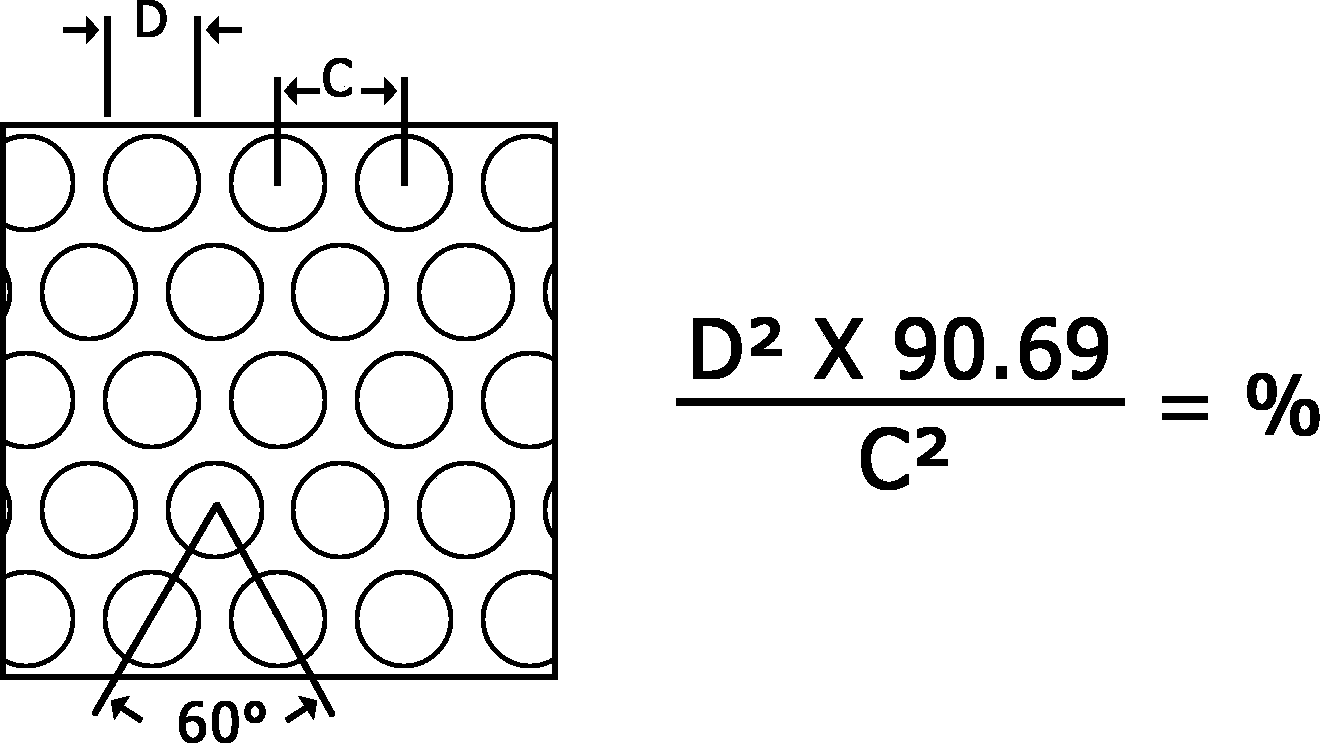

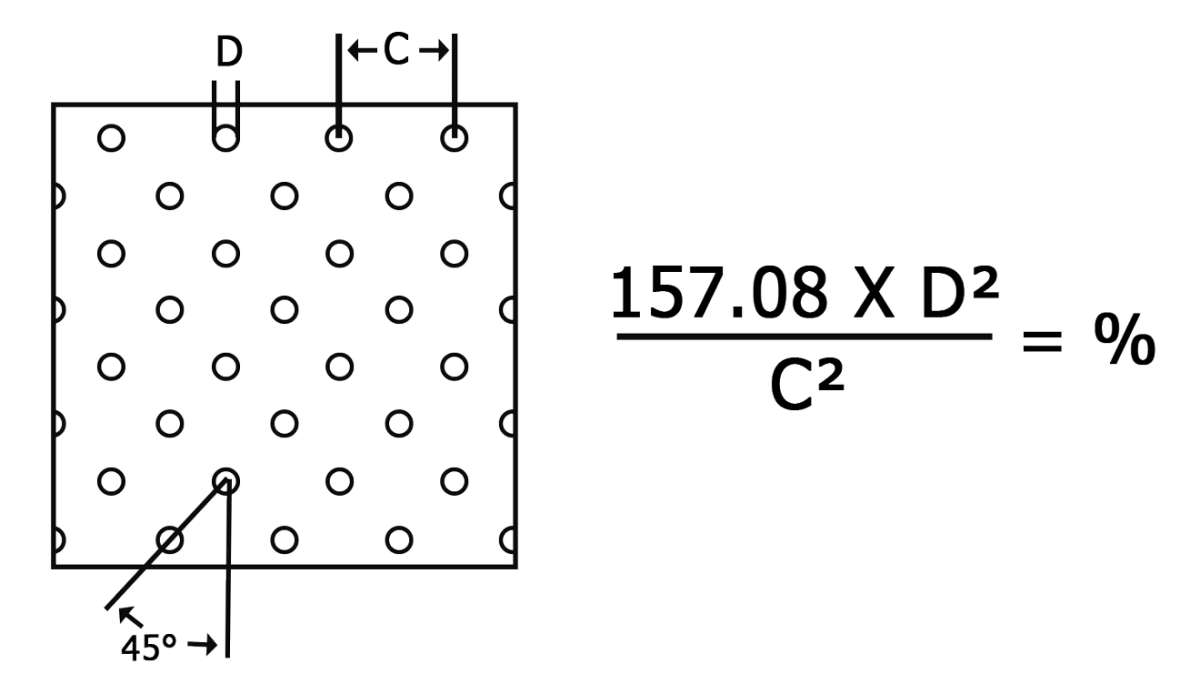

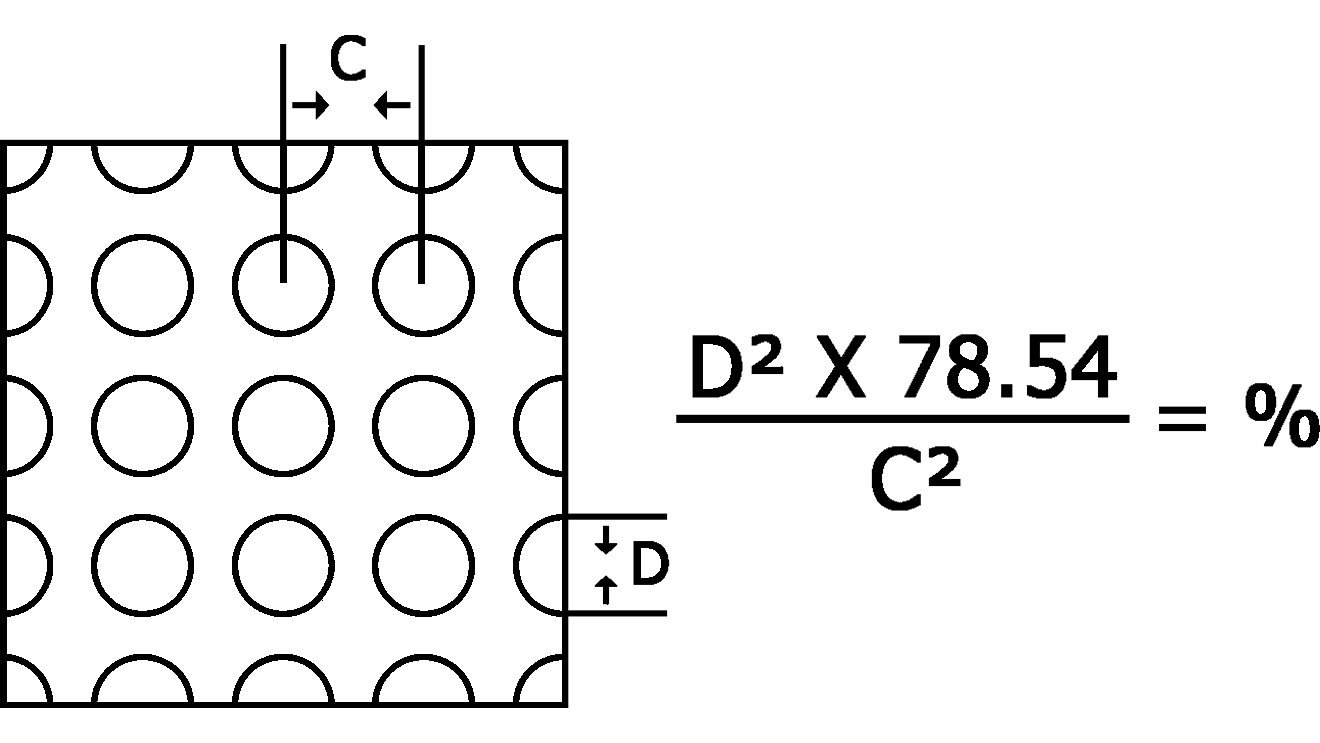

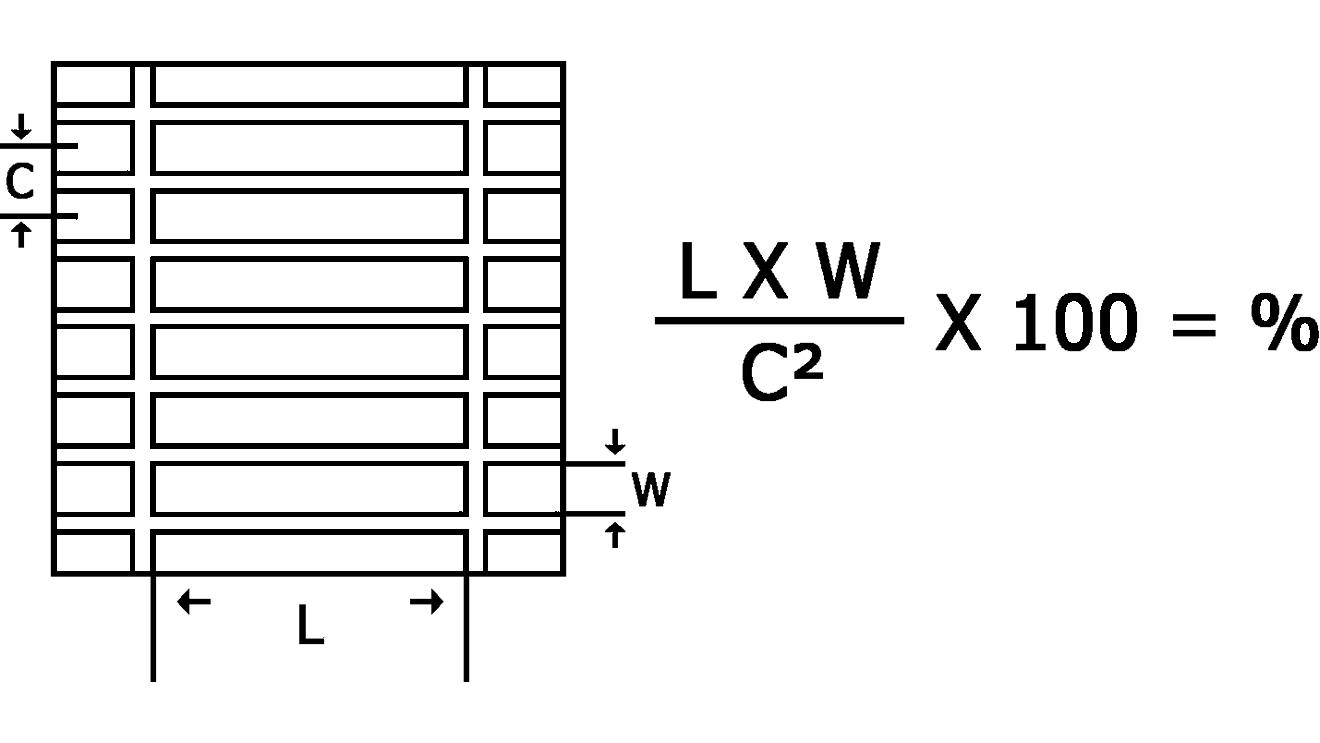

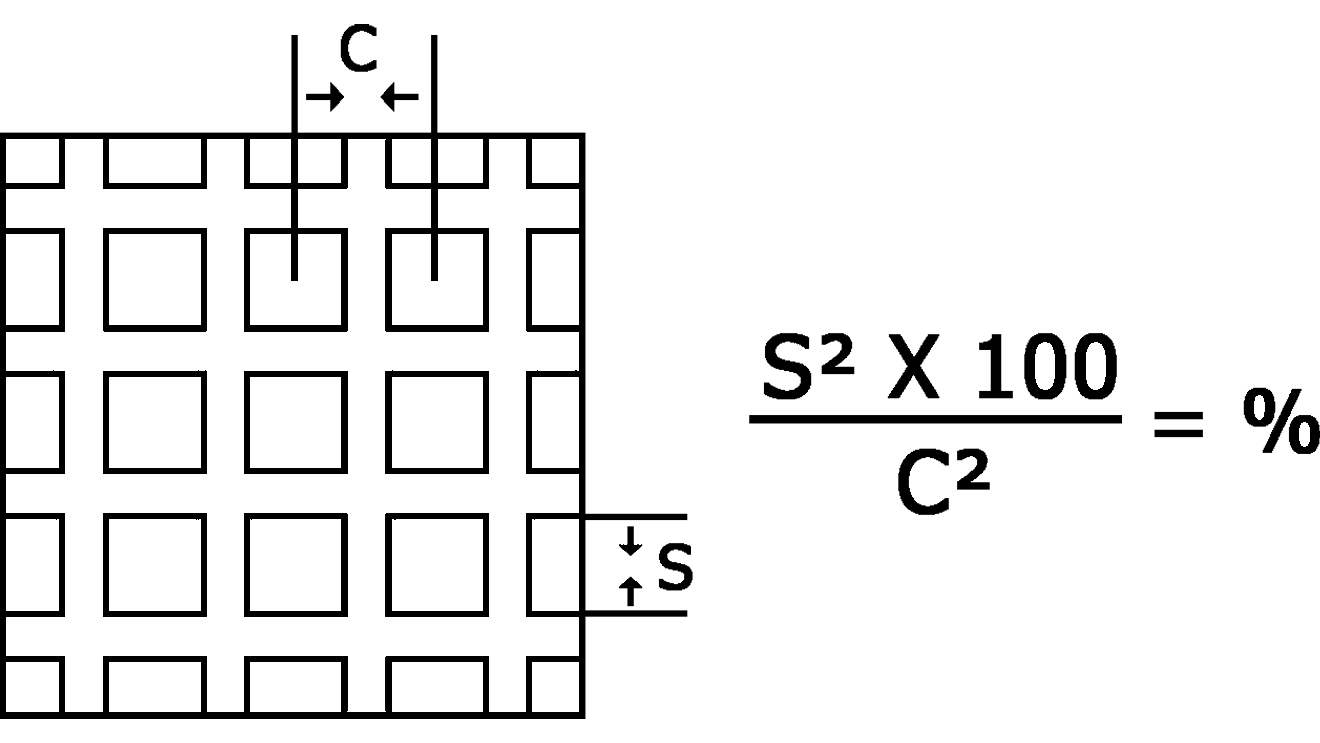

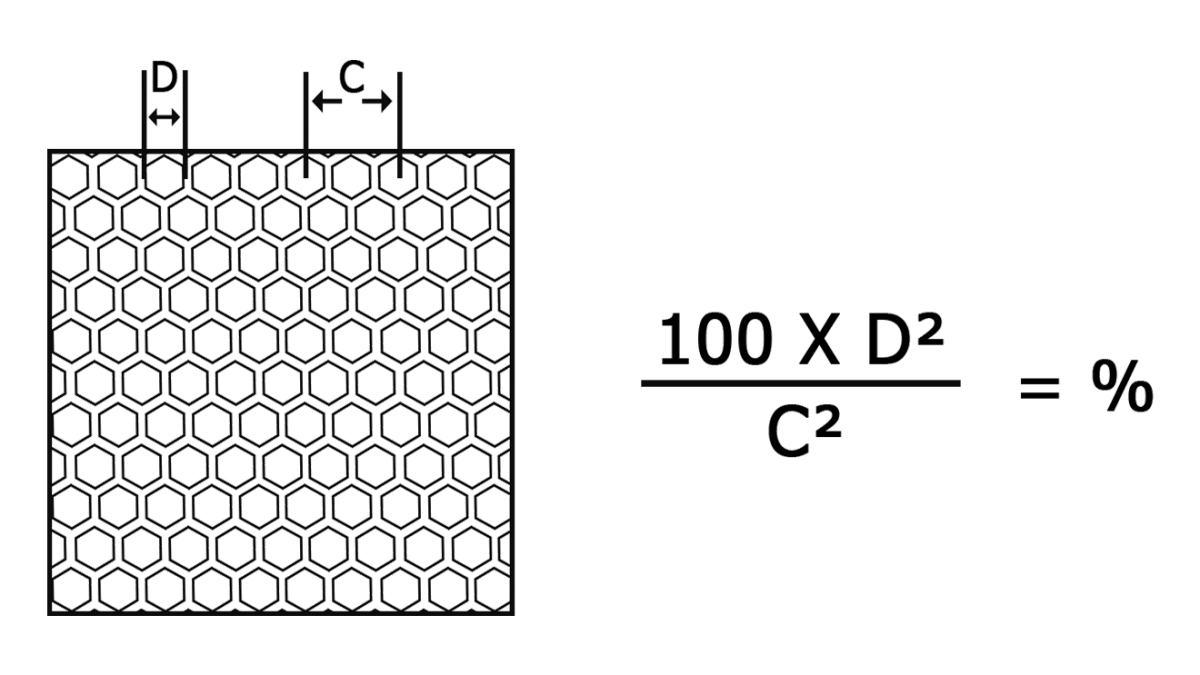

- Open Percent Formulas

Perforation Material

- Stainless Steel Perforated Metal

- Aluminum Perforated Metal

- Galvanized Steel Perforated Metal

- Steel Perforated Metal

- Brass Perforated Metal

- Titanium perforated Metal

Perforated Filter Series

- Perforated Filter Disc

- Stainless Steel Perforated Tube

- Aluminum Perforated Tube

- Spiral Welded Perforated Tube

- Spiral Lock Seam Tube

- Conical Strainer

- Basket Strainer

- Perforated Filter Elements

Perforated Metal Curtain Wall

- Perforated Metal Facade

- Aluminum Perforated Facade Panel

- Aluminum CNC Laser Cutting Panel

- Aluminum Expanded Facade Panel

- Perforated Metal Cladding Panels

Spiral Lock Seam Tube

Lock seam perforated pipe is made by folding up the overlapping edges against each other, then folding them over in the same direction a number of times. It has flush surface outside and lock seam inside. This type perforated tubing is the popular option of fluid filtration like center tube in the filter house.

Mild steel and stainless steel are common materials of manufacturing spiral perforated tubes. For generally applications, carbon steel is available to serve. However, for corrosive work conditions, stainless steel perforated pipe is a cost-efficient choice in the long terms.

Specifications:

Material: mild carbon steel, stainless steel or as ordered;

Hole diameter: no less than 1.0mm;

Open area: up to 65%;

Thickness:0.2mm to 0.7mm;

Outside diameter:20mm to 200mm;

Length: up to 1500mm.

Applications:

Filter liquids and air, such as water, oil, etc.

Sieve different materials and remove impurities, such as in food, pharmaceutical, chemical and environmental protection industry.

As various frameworks of filter elements.

Weaken the noise.

Used for granary ventilation.